SAXS/WAXS有助于阐明泡沫的结构和功能之间的关系

泡沫(固体或液体中的气体)是我们身边常见的材料。液体泡沫可用于化妆品配方,家庭护理产品及食物,而固体泡沫则用于汽车、航天和飞机的坐垫、绝缘和轻型结构中。固体泡沫是具有低密度和热导率的多孔材料。这些特性加上高能量吸收和隔音,使泡沫成为一种理想的包装材料、减震器和隔音器。

为了对这些泡沫的机械性能进行建模、预测及定制,需要对壁厚、孔径尺寸、形状及排列进行全面的表征。在较小的长度尺度上,制造过程本身也会对机械性能产生影响。聚苯乙烯,聚乙烯,聚丙烯,聚氨酯树脂和聚乳酸等热塑性塑料常被用于泡沫的基础材料,热历史和结晶度以及晶型和取向已被证明是影响泡沫对机械应力反应及其破坏行为的主要因素。由于需要探测的尺度范围很大,因此散射技术(静态和动态光散射、扩散波光谱和小角广角中子X射线散射)对泡沫的全面表征非常重要。

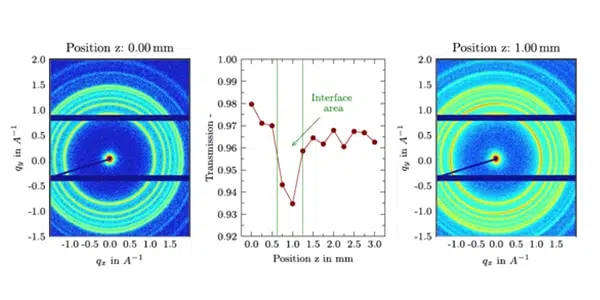

在德累斯顿工业大学和德累斯顿莱布尼茨聚合物研究所合作发表的一篇文章中[1] ,研究人员证明了对基础材料充分了解的重要性,以及将聚丙烯(PP)加工成闭孔球状泡沫过程中所经历的改性。通过广角X射线散射(WAXS)测试,他们能够发现PP中α- β- 和 γ-相的绝对数量。与成型的材料相比,原始的材料具有不同比例的结晶相。此外,这些实验揭示了成型过程中加入的原材料结晶组分的变化。最后,二维WAXS实验表明,pp在颗粒材料结合的连接处和原材料外表皮层是取向的(见右下图),具有较低的透射率,而在内部区域显示是无定向的(左下图显示各向同性散射)。结晶度可以很好地推断出这些材料的应力-应变曲线。

Credit: International Journal of Engineering Science, 2019, doi: 10.1016/j.ijengsci.2019.103168

用SAXS和WAXS表征泡沫的最新例子中,揭示了不通过温度对PHBV泡沫结晶的影响。研究人员发现在不同的加工温度下,晶体形态保持不变。然而,长周期距离存在差异,长周期代表结构域之间的平均距离,特别是原始和泡沫PHBV之间的距离。他们认为,发泡过程降低了晶体成核所需的能量,从而导致片晶增厚[2] 。

最后一项研究详细介绍了拉伸对热塑性聚氨酯(TPU)的影响[3] 。TPU呈现出微相分离,柔性链段形成连续相,刚性域均匀分布,形成物理交联。他们发现热塑性聚氨酯(TPU)泡沫在拉伸过程中长周期增大,当去掉拉伸力后,长周期也减小。拉伸过程中刚性结构距离的增加可以通过柔性链沿伸长方向的延伸来解释。在明显高于柔性链段玻璃化转变温度的温度下去除外力会导致柔性域的链松弛。

这些结果表明,研究不同类型聚合物基泡沫在动态外部条件下(如温度和应力变化)的结晶性能,SAXS/WAXS是理想且有效的工具。